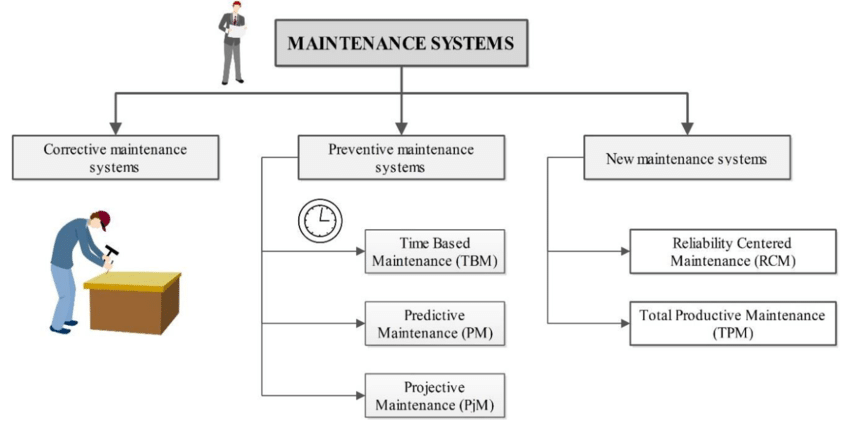

Preventive Maintenance System

Preventive maintenance, or PM, is regular, planned maintenance that is scheduled by maintenance triggers, including time, usage, event, and condition. The purpose of PM is to lessen the likelihood of

Preventive maintenance, or PM, is regular, planned maintenance that is scheduled by maintenance triggers, including time, usage, event, and condition. The purpose of PM is to lessen the likelihood of

The main question that maintenance managers face is whether their output is produced effectively, in terms of contribution to company profits, and efficiently, in terms of resources. In the manufacturing

Background Just before moving to the United Kingdom in 2015 for my master’s degree in electronic and electrical engineering at the University of Leeds, I was asked by Shirley, “what would

Standard Operating Procedures (SOPs) ensure consistency and efficiency in maintenance practices by standardizing activities, ensuring uniform task execution regardless of the technician. When implemented correctly, they improve maintenance work speed

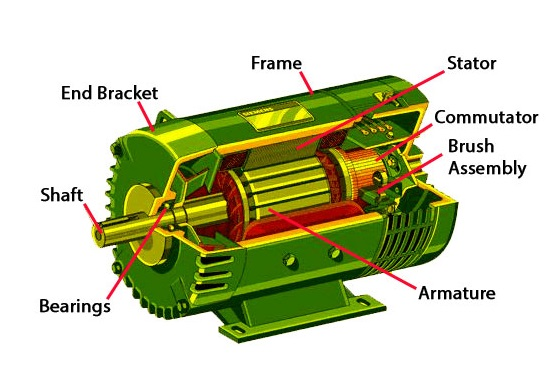

A well-designed preventive maintenance program ensures dependable, long-lasting electric motor operation. Electrical equipment demands regular inspections and maintenance for optimal performance. This is crucial for electric motors. Routine inspections at

🔍 Seeking operational excellence? Dive into the power of Standard Operating Procedures (SOPs) and discover how they can revolutionize your organization! From enhancing consistency to boosting productivity, SOPs are the

## The Secret Sauce of Operational Excellence: Processes, Procedures, and Work Instructions **Want to achieve consistency, quality, and efficiency in your organization?** Look no further than standard work!

## Don't Let Your Profits Leak! How Manufacturing SOPs Save You Money **Ever feel like money is slipping through your fingers in your manufacturing operation?** You're not