Key Metrics for Effective Preventive Maintenance (PM) Program Management

In the realm of maintenance management, four crucial metrics stand out for evaluating and optimizing your Preventive Maintenance (PM) program:

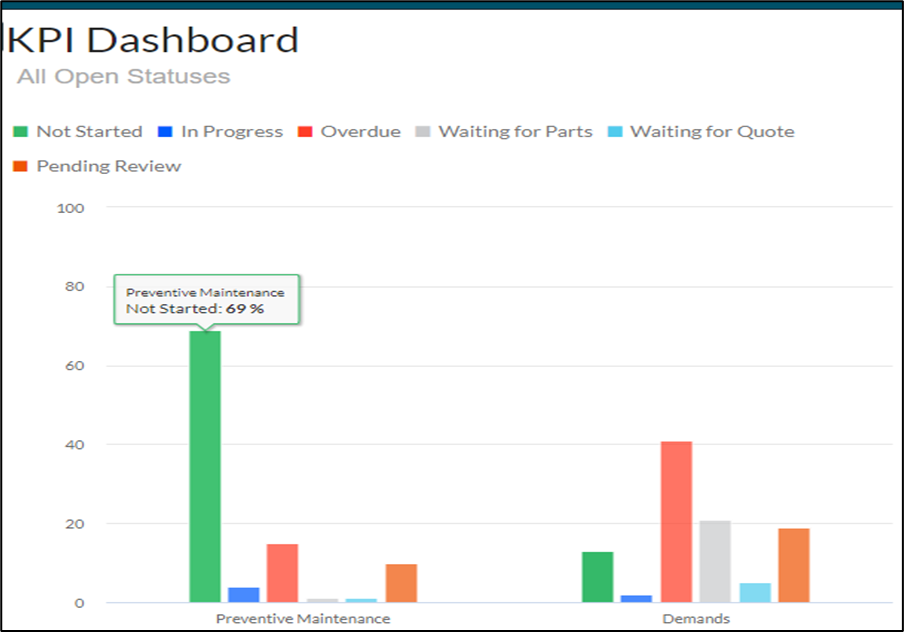

1. PM Execution Rate or compliance

This metric gauges the percentage of scheduled PMs completed within a specified timeframe. Aim for a completion rate exceeding 95%, with 98% being ideal. Consistent monthly performance is crucial. A grace period of 10% of the scheduled interval (up to 30 days) is typically allowed.

Timely PM execution is fundamental to assessing the effectiveness of your maintenance strategy. Without consistent implementation, it becomes challenging to evaluate the impact of your PM efforts.

2. Preventive to Corrective Maintenance Ratio

This indicator compares the time invested in preventive tasks versus corrective actions. Calculate it by dividing PM hours by Corrective Maintenance (CM) hours for a given period.

The ideal ratio varies based on equipment type and maintenance strategy. For instance:

- Run-to-failure assets (e.g., general lighting) should show a low PM/CM ratio.

- Critical systems (e.g., emergency lighting) typically require more preventive work, resulting in a higher PM/CM ratio.

Misaligned ratios may signal the need for strategy adjustments.

3. PM Cost and Time Analysis

Identify opportunities for improvement by examining:

- Top 20 systems with the highest annualized PM costs

- Top 20 systems consuming the most PM hours annually

- Individual PM tasks with the highest resource demands

This analysis helps pinpoint areas where PM efforts might be excessive or insufficient.

4. PM-Initiated Work Orders

This metric reveals how often PMs lead to additional maintenance tasks. It helps answer:

- Are our PMs effectively identifying issues?

- Are we potentially over-maintaining certain assets?

A low rate of follow-up work might indicate overly frequent inspections or unnecessary PM tasks. However, interpret this metric cautiously, as it’s not a definitive measure but rather a prompt for further investigation.

Very insightful.

443206 176755I saw your post awhile back and saved it to my computer. Only recently have I got a chance to checking it and have to tell you nice work. 313743