Feedback to Preventive Maintenance from Corrective Maintenance

A good preventive maintenance program does not immediately eradicate the possibility of breakdowns or defects. But what you do with the information from the event will affect the outcome of the PM system in the long run. As a maintenance manager, one of the best practices is to have a feedback system for preventive maintenance based on failure analysis. This is a simple approach that can yield positive results, especially when countermeasures from the root cause analysis are implemented as add-ons to the existing preventive maintenance task lists.

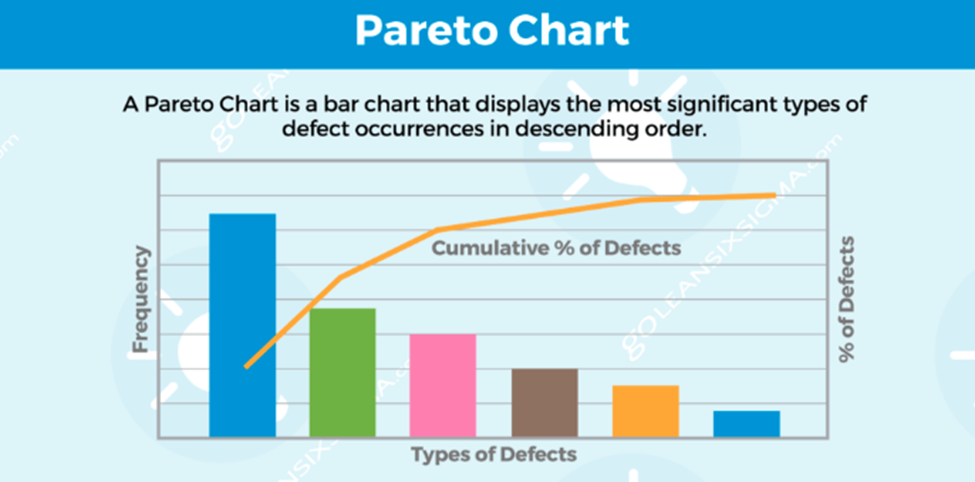

The best approach is to use data and follow the Pareto principle. This is done by plotting the number of corrective maintenance activities done per piece of equipment for the previous week. It should be noted that corrective maintenance does not always result from a breakdown, but any demand work order performed on a piece of equipment to prevent failure or defect. By so doing, the preventive maintenance task list is enriched with learnings from corrective maintenance, subsequently preventing future failure occurrences through PM execution.

#MAINTENANCE #RELIABILITY #SOP #PLANNING #CMMS #SQUAREMETHODS #TRAINING #TASKLIST