Experience from Breakdown: Lessons for Maintenance Managers

While breakdowns are often seen as a nightmare by production managers, the value they provide to maintenance managers is significant. Even with a strong commitment to preventive maintenance, a hard truth remains: without documented experiences of failures, maintenance personnel may not fully understand what to look for during maintenance execution. The OEM maintenance task list is invaluable, but knowing how to carry out the inspection and maintenance is an entirely different challenge.

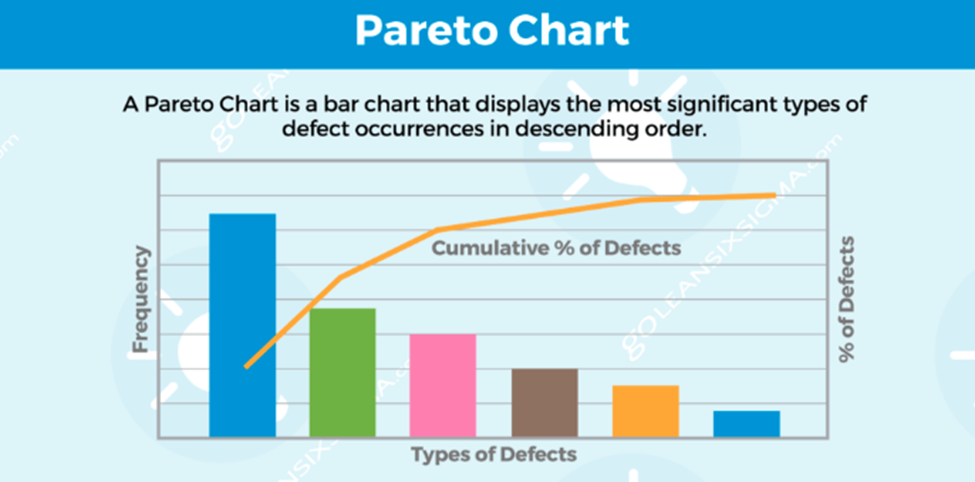

Research into the dominant root causes of failures in the manufacturing industry has shown that issues related to human error and improper methods contribute to more than 90% of total breakdowns and downtime. These problems often stem from deficiencies in the functional competencies required to perform quality maintenance across various aspects of the manufacturing system. The complexity of machines’ working principles and parts assemblies further exacerbates these issues.

Theoretical knowledge from machine manuals and training illustrations, while helpful, may not be explicit enough without actual experience and detailed knowledge gained from resolving issues directly on the machine. In other words, failures offer an opportunity to understand the internal mechanisms of the machine, and the troubleshooting process validates the actual principles of operation.

For this reason, a maintenance manager should be present as much as possible during breakdown resolutions. The knowledge gained from the disassembly, visualization, and reassembly of the machine should be used to create practical work instructions for technicians. Knowing what needs to be done is one thing; knowing how to do it and what to look out for while executing the maintenance task is another.