Maintenance Execution: What to do

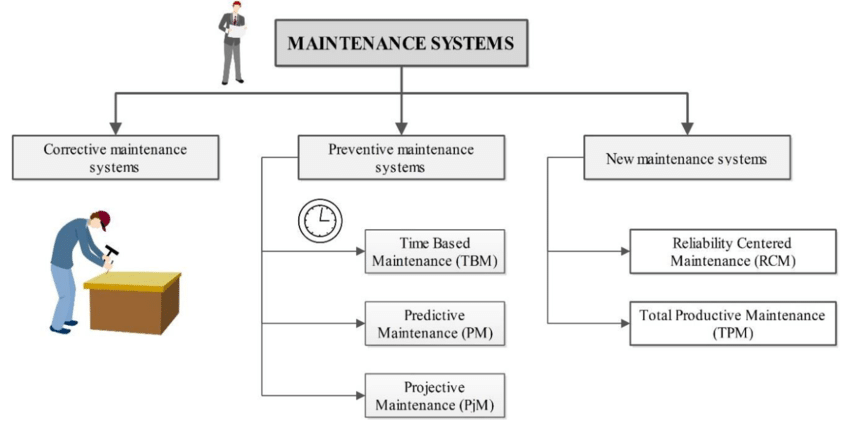

Based on the reliability-centered maintenance principle, understanding what needs to be done to keep equipment in a sustainable reliability state sets the maintenance process of identification of failure modes in motion for successful eradication through countermeasures. To get started, these questions must be addressed.

1. What is the working principle of the asset or equipment, and what are the associated performance standards?

2. What are the assemblies, components, and parts of the machine that require maintenance? They are referred to as maintenance significant items (MSI).

3. In what ways can the maintenance significant items fail to provide the required functions? This involves failure mode identification.

4. What event can trigger each failure?

5. What are the noticeable signs and possible effects when each failure occurs?

6. What are the risks of failure?

7. What systematic proactive task can be done to prevent or diminish the consequences of the failure?

#MaintenanceExecution #OperationalExcellence #IndustrialMaintenance #AssetManagement #PreventiveMaintenance #MaintenanceStrategies #Efficiency #Reliability #MaintenanceManagement #OperationalEfficiency #MaintenanceBestPractices #MaintenancePlanning #MaintenanceOptimization #IndustrialEngineering #MaintenanceExecutionTips #blog.Squaremethods.com