Create work instructions that work

Maintenance work instructions are essential documents that outline the specific steps for performing maintenance tasks. These instructions should be detailed enough for a competent technician, even if new to the facility, to complete the work successfully and safely. The goal is to identify and document the most efficient, effective, and safest method for each task, recognizing that this process may evolve over time.

To create impactful work instructions, consider these key principles:

1. Clarity and Accessibility: Instructions should be easy to read, use, and locate. Use concise language and avoid unnecessary preambles.

2. Consistency: Employ a standardized template across all work instructions to maintain uniformity.

3. Logical Sequence: Organize complex tasks into phases, grouping related steps to minimize errors.

4. Value-Added Content: Include critical information that technicians might not remember while avoiding redundant generic text.

5. Up-to-date and Comprehensive: Regularly update instructions to maintain their relevance and trustworthiness.

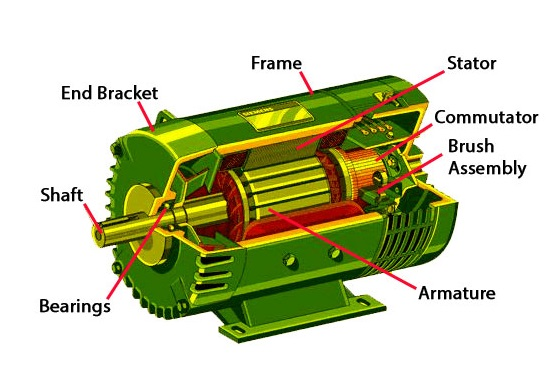

6. Visual Aids: Incorporate diagrams or photos when they enhance understanding, but use them judiciously.

7. Highlight Critical Steps: Use visual cues to emphasize crucial safety or quality-related steps.

8. Verification Processes: For high-risk tasks, include steps for independent verification.

9. Document Control: Treat work instructions as formal documents with proper versioning and approval processes.

10. Integration with Training: Use these instructions in competency development and assessment of new technicians.

By adhering to these principles, maintenance teams can create work instructions that not only guide task completion but also contribute to a culture of continuous improvement and safety. Remember, the ultimate goal is to provide clear, practical guidance that technicians will trust and utilize in their daily work.