Assigning maintenance resource

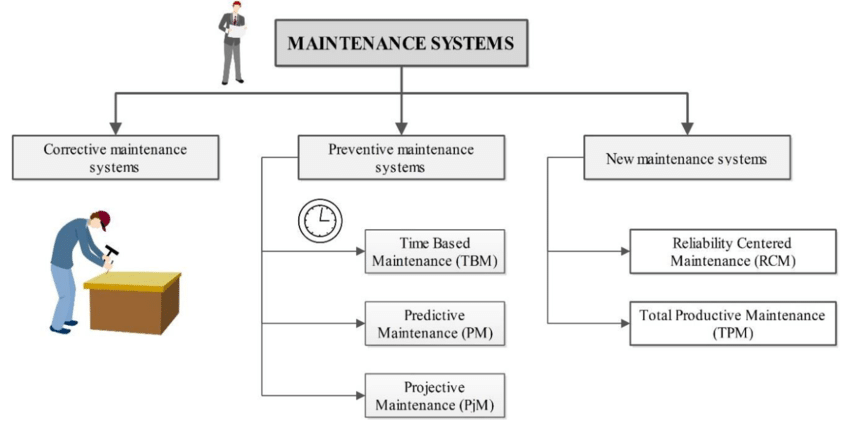

One fateful morning, I walked up to the human resources director to justify an extra hand in the maintenance department. While the discussion was ongoing, I was asked, “How much time do you think a technician should be free?” A technician, like everyone else, should be busy with maintenance on the line for at least seven (7) hours of an eight-hour shift, with one (1) hour off. Technically speaking, this is correct. As a maintenance engineer, I find this analogy faulty. I noticed the reason behind the unwillingness to increase manning in the engineering department as opposed to the production department. Justification must be made based on data and understanding.

According to my years of experience in maintenance engineering, the majority of inspection jobs require only one person, whereas the majority of repair jobs require two. Although two (2) people are required for most corrective actions, only a licensed technician’s expertise is needed. With this proposition, a minimum of two technicians are needed on every shift to carry out planned maintenance and any other breakdowns that may come up during the shift. This minimum number is critical, especially when some repairs require extra hands for lifting, supporting, and testing. For a plant with technical operators, one technician might be enough, otherwise, a second technician is required.

A significant factor to consider is the prevailing number of minor interventions and breakdowns on the running equipment. When these numbers are at their minimum, then two technicians are enough to carry PM separately on available machines while rendering support to each other as the job might demand and also supporting production. When the number of interventions on running equipment is considerably high, the manning requirement becomes complicated because productivity is reduced, PM execution is drowned, and any request for extra manpower comes at an additional cost.

My expert advice on this is to have a proper line-balancing system to allocate workers to machines according to the expected number and duration of tasks to be executed on the machines per day. Hence the need for proper tracking of job execution. With proper tracking of resource utilization (man-hours) by the technicians, a proper justification can be made without compromise.

#MAINTENANCE #RELIABILITY #SOP #PLANNING #CMMS #SQUAREMETHODS #TRAINING #TASKLIST