Maintenance System

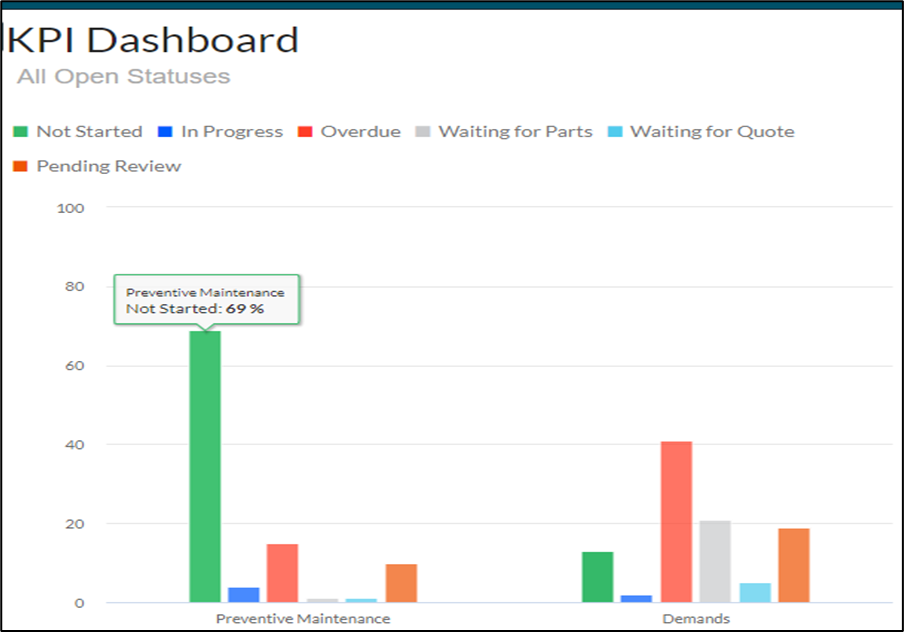

The main question that maintenance managers face is whether their output is produced effectively, in terms of contribution to company profits, and efficiently, in terms of resources. In the manufacturing industry, maintenance costs are a growing concern for stakeholders, and optimization of these costs is a key performance index for the maintenance management team.

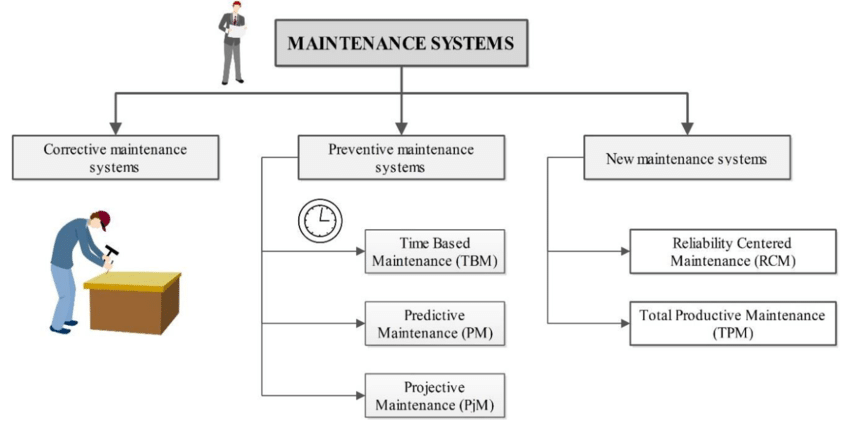

The main objective of plant maintenance is to maximize the return on investment of physical assets. The main drivers of this objective are installation performance and maintenance costs. As simple as this may sound if you don’t have a proper maintenance system, maintenance functions would be more like firefighting, while the associated cost breakdown would continue to skyrocket.

Author