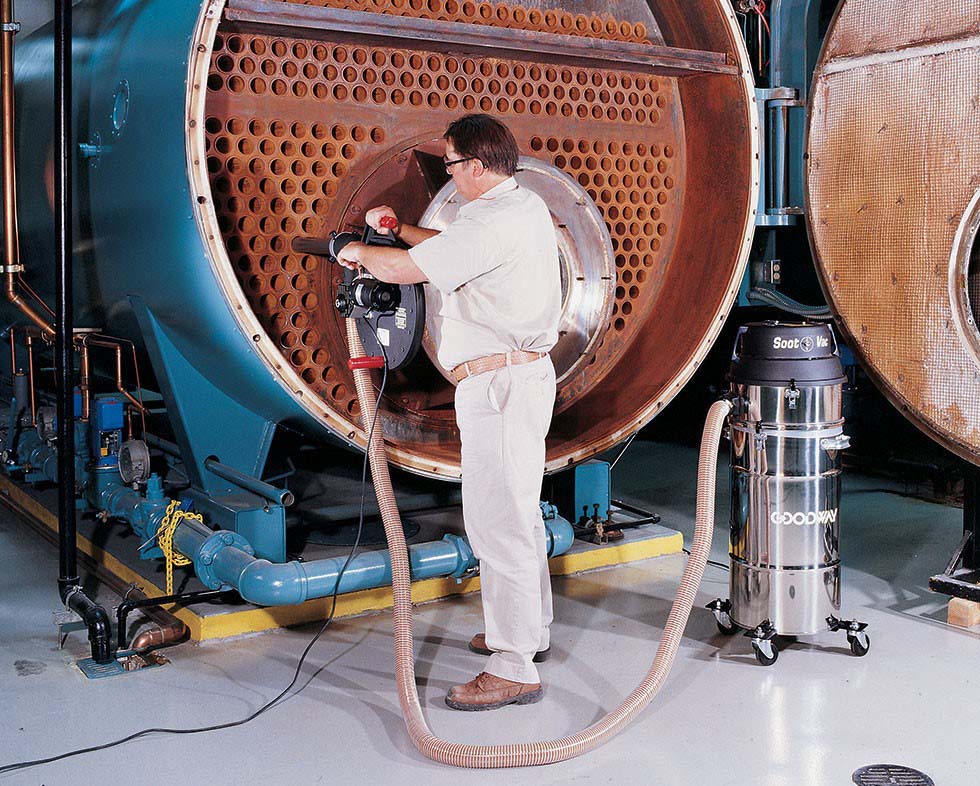

Cleaning, the First Line of Maintenance

In the realm of industrial maintenance, where machinery and equipment are the lifeblood of operations, an often underestimated yet foundational aspect is cleaning. The saying “cleanliness is next to godliness” holds true in the industrial context, where cleaning serves as the first line of defense against wear and tear, malfunction, and potential safety hazards. In this blog post, we delve into the critical role of cleaning as the initial step in maintenance practices and explore how a pristine environment sets the stage for operational excellence.

Understanding the Nexus of Cleaning and Maintenance:

1. Preventing premature wear:

Industrial equipment is subjected to harsh conditions, from dust and debris to chemical residues. Regular cleaning removes contaminants that can accelerate wear on moving parts, ensuring that machinery operates smoothly and efficiently. This proactive approach helps prevent premature wear and extends the lifespan of critical components.

2. Mitigating the Risk of Malfunctions:

Clean equipment is less susceptible to malfunctions. Dust, dirt, and grime can infiltrate sensitive electronic components, leading to electrical issues and malfunctions. By keeping equipment clean, maintenance teams reduce the risk of unexpected breakdowns, minimizing downtime and optimizing operational continuity.

The Impact on Safety and Compliance:

3. Enhancing Workplace Safety:

A clean industrial environment is a safer one. Clutter, spills, and debris pose significant safety risks, increasing the likelihood of accidents. Regular cleaning not only removes physical hazards but also fosters a culture of safety awareness among employees, reducing the incidence of workplace injuries.

4. Meeting Regulatory Standards:

Many industries are subject to strict regulatory standards concerning hygiene and cleanliness. Adhering to these standards is not just a legal requirement but also a key aspect of responsible industrial stewardship. Regular cleaning ensures compliance with regulations, protecting both employees and the organization from potential legal repercussions.

Cleaning as a Proactive Maintenance Strategy

5. Identifying Potential Issues Early:

Cleaning provides an opportunity for maintenance teams to inspect equipment closely. During the cleaning process, technicians can identify signs of wear, corrosion, or damage that may require attention. This proactive approach enables early intervention, preventing minor issues from escalating into major problems.

6. Optimizing Operational Efficiency:

A clean and well-maintained industrial environment is inherently more efficient. Clean equipment operates with higher energy efficiency, reducing operational costs. Additionally, a well-organized and clutter-free workspace facilitates smoother workflows, contributing to overall operational excellence.

Implementing a Comprehensive Cleaning-Maintenance Program:

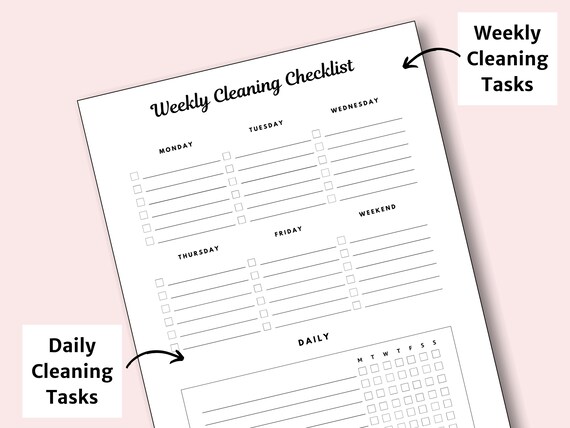

To harness the full potential of cleaning as the first line of maintenance, organizations should establish a comprehensive cleaning-maintenance program. This program should include:

- Regular cleaning schedules for equipment and workspaces.

- Training for employees on proper cleaning procedures.

- Integration of cleaning into overall preventive maintenance plans.

- Utilization of suitable cleaning agents and tools for different types of equipment.

In conclusion, cleaning stands as the cornerstone of effective industrial maintenance. By recognizing the symbiotic relationship between cleaning and maintenance, organizations can lay the groundwork for operational excellence, ensuring the longevity, safety, and efficiency of their industrial assets. Embracing a culture where cleaning is not just a task but a strategic imperative sets the stage for a robust and resilient industrial maintenance framework.

Author Linkedin