10 Rules for Effective Work Instructions

Maintenance work instructions are a written set of instructions that specify how a maintenance task is to be performed.

Maintenance work instructions are a written set of instructions that specify how a maintenance task is to be performed.

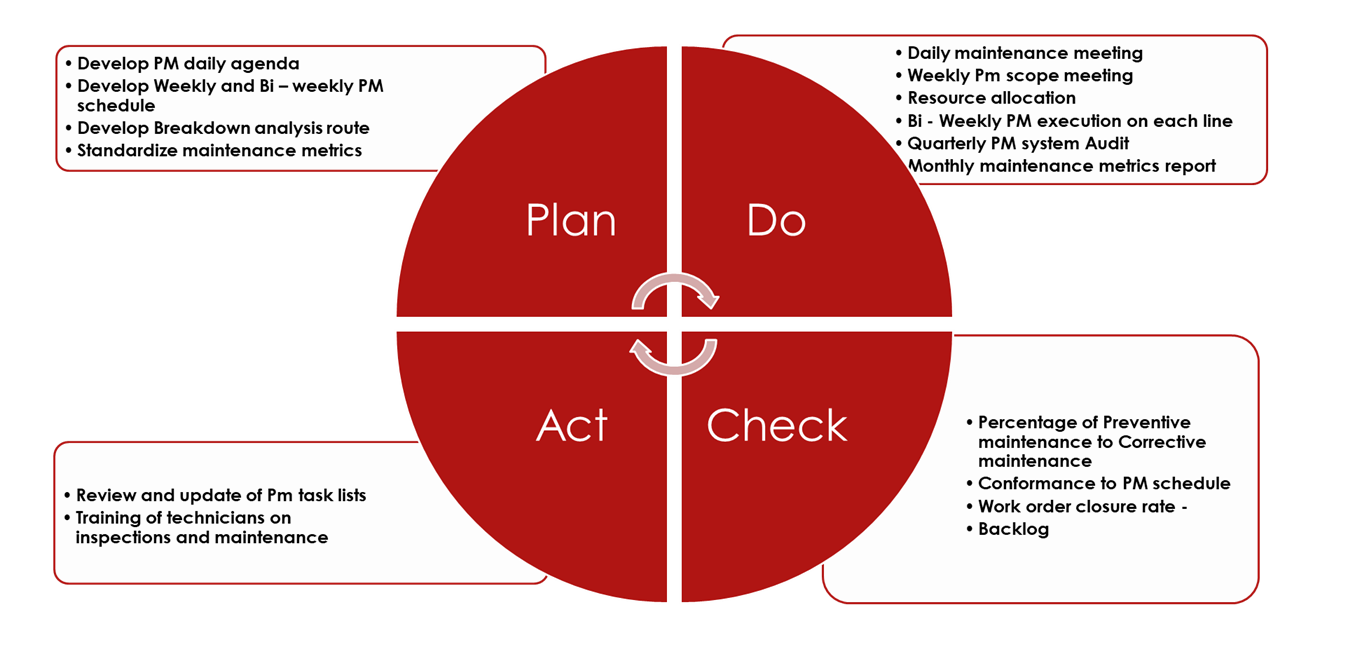

While these metrics provide valuable insights, remember that effective PM program management requires a holistic approach.

Charlie Munger, an eminent investor in his own right, expressed several Buffettesque investment principles.

Low population density and vast distances between cities limit manufacturers in some regions. This creates small markets and high logistics costs, affecting business strategies and pricing.

One fateful morning, I walked up to the human resources director to justify an extra hand in the maintenance department.

A clear description of fault finding and repair information is crucial for effective root cause analysis and in providing subsequent countermeasures.

A shop floor excellence audit is used to check the effectiveness of the maintenance team in keeping the machine in basic condition.

You don’t have to break the bank to get a computerized maintenance management system (CMMS).

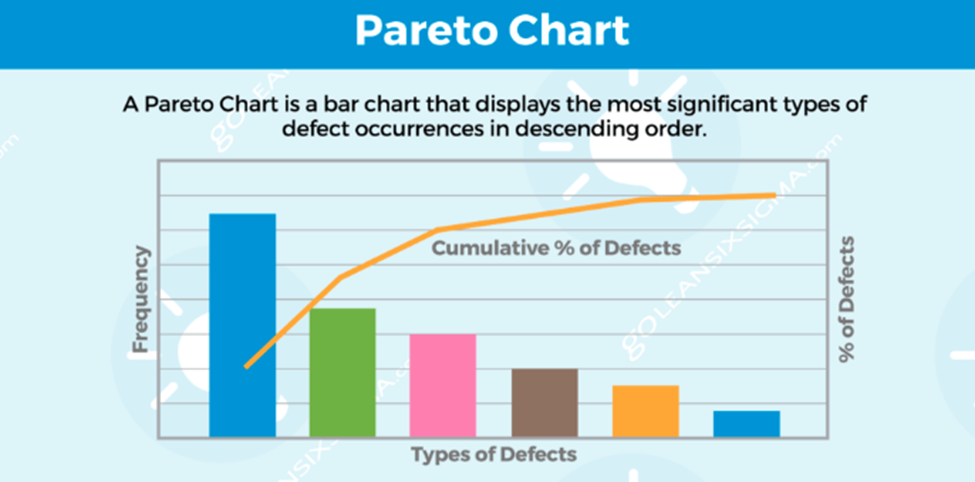

A good preventive maintenance program does not immediately eradicate the possibility of breakdowns or defects. But what you do with the information from the event will affect the outcome of

A prerequisite is a standard roadmap to detail various action plans to create a good preventive maintenance system.