How Amazon Monitron Helped Reduce Maintenance Costs by 20%

One of the most compelling reasons to adopt Amazon Monitron is the potential for significant cost savings. In this blog post, we explore how our recent project led to a reduction in maintenance costs for our client by 20%.

Initial Challenges:

Our client was spending a substantial amount on reactive maintenance. Unplanned downtime due to equipment failures often led to emergency repairs, overtime pay, and lost production time.

Monitron Implementation:

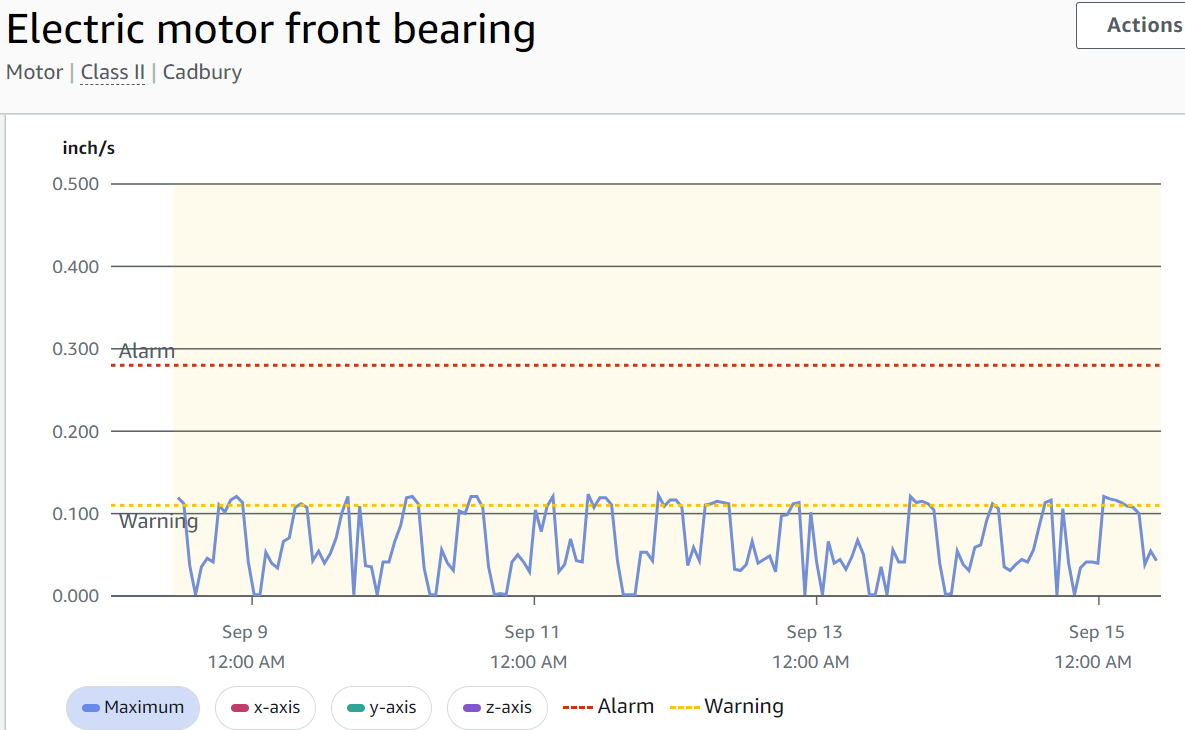

We deployed Amazon Monitron to monitor key machinery, focusing on equipment that had a history of frequent breakdowns. The system’s ability to track vibration and temperature in real-time meant that we could identify potential issues before they escalated.

Cost Savings:

The immediate impact was a reduction in emergency maintenance calls. By acting on the data provided by Monitron, the client could schedule repairs during planned downtime, avoiding costly interruptions to their operations. Over the first six months, they reported a 20% reduction in overall maintenance costs.

Long-Term Benefits:

Beyond the initial savings, the client has seen improvements in equipment longevity and operational efficiency. The insights provided by Amazon Monitron have enabled them to optimize their maintenance schedules, further reducing costs and improving their bottom line.

Interested in how Amazon Monitron can help your business achieve similar results? Let’s discuss how we can tailor a solution to meet your needs.