A Comprehensive SOP Guide

Standard Operating Procedures (SOPs) ensure consistency and efficiency in maintenance practices by standardizing activities, ensuring uniform task execution regardless of the technician. When implemented correctly, they improve maintenance work speed and quality, reducing downtime, enhancing equipment longevity, and boosting asset performance over time. This guide provides a comprehensive approach to developing and implementing SOPs that align with specific maintenance needs and regulatory requirements.

- Define Scope and Objectives

Clearly identify the SOP’s purpose and goals, such as improving efficiency, ensuring safety, or complying with regulations. Understand the maintenance activity, equipment involved, and required skills for efficient and safe task performance.

Prioritize critical processes and equipment, focusing first on areas with significant safety concerns to minimize risks. Then, address audits, non-critical equipment inspections, and other activities to standardize.

- Gather Necessary Information

Collect data on current maintenance practices, equipment usage, OEM manuals, operating conditions, equipment conditions, and past failures. Analyze this information to identify trends, common issues, and areas for improvement to address in the SOPs.

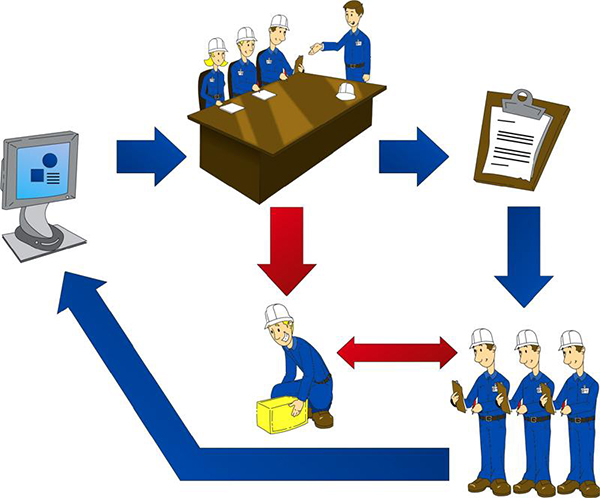

Consult maintenance technicians and machine operators for valuable insights, ensuring SOPs are technically sound and practical.Review existing maintenance records and practices to understand the current state, identify strengths and weaknesses, and establish a baseline for measuring the new SOPs’ effectiveness.

- Consult Experts and Stakeholders

Incorporate feedback from various departments to understand how maintenance tasks impact other areas, ensuring SOPs align with broader organizational goals and activities.

Collaborate with quality assurance, production, and safety teams to address common defects, production issues, and compliance with regulations and safety standards.

- Consider the SOP Users

Present content clearly and concisely, using language and terminology familiar to the users. Adjust the level of technical detail based on the users’ expertise, ensuring accessibility and practicality.

- Include Visuals and Safety Guidelines

Outline required safety steps and precautions. Include visual aids like videos, flowcharts, diagrams, schematics, and annotated images to break down complex procedures and enhance understanding.

Utilize digital formats, such as SquareMethods, to enable the use of visual aids, mobile access, and easy updates.

- Review and Update Regularly

Regularly update SOPs to reflect changes in technology, tools, equipment, regulations, and maintenance processes, ensuring practices remain effective, efficient, and compliant with industry standards and legal requirements.

By following these guidelines, organizations can achieve a higher standard of efficiency, safety, and regulatory compliance, ultimately leading to a more sustainable and successful maintenance operation.