How SOPs Can Become Your Manufacturing Secret Weapon

Every manufacturer understands the struggle. You’re constantly looking for ways to squeeze more efficiency out of your operation. How can you produce more with less? Reduce waste? Ultimately, increase your profit margin? There’s an often-overlooked hero in this quest for efficiency: Standard Operating Procedures (SOPs). These seemingly simple documents can quietly contribute to significant cost savings. But how exactly do SOPs work their magic? Let’s dive deeper and explore the ways these silent money savers can transform your manufacturing floor.

1. Doing it Right the First Time: Eliminating the Cost of Errors

Imagine a world where every task on the factory floor is completed correctly, the first time around. No wasted materials, no production delays due to rework. SOPs make this a reality. By providing clear, step-by-step instructions, SOPs ensure everyone is on the same page, regardless of experience level. This reduces errors and rework significantly.

Consider a scenario where a new employee assembles a product incorrectly. Not only are the materials wasted, but additional time and resources are needed to disassemble, troubleshoot, and reassemble the product. Studies by the International Society of Automation (ISA) have shown that a 20% increase in Overall Equipment Effectiveness (OEE) can lead to substantial profit gains. SOPs directly contribute to OEE improvement by minimizing errors and ensuring equipment is used correctly, leading to less downtime and higher production output.

2. Quality You Can Count On: Avoiding Costly Recalls and Defects

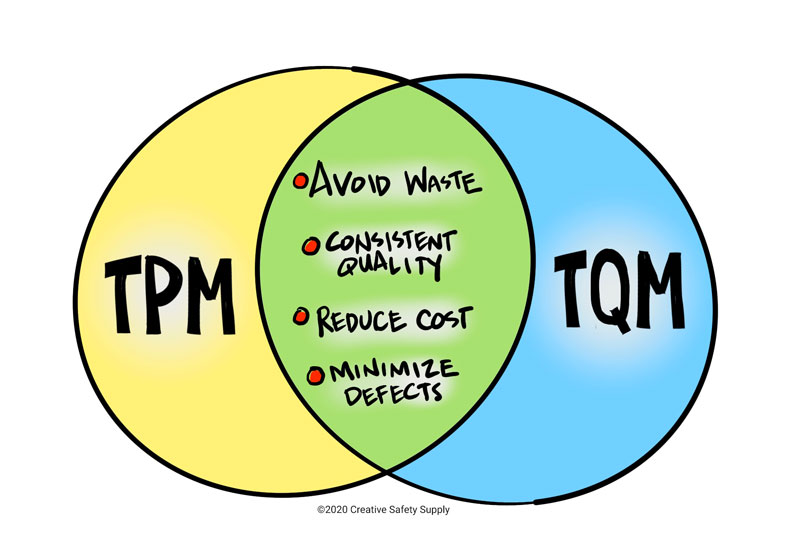

Consistent quality is the cornerstone of any successful manufacturing operation. Inconsistent quality can lead to a domino effect of problems – unhappy customers, returns, potential safety hazards, and worst-case scenario, product recalls. SOPs help achieve consistent quality by outlining the specific processes and protocols needed for each product. This includes things like material specifications, equipment settings, and quality control checkpoints. By following these established guidelines, manufacturers can ensure their products meet strict quality standards, reducing the risk of defects slipping through the cracks.

The cost of a product recall can be astronomical. Just look at the Takata airbag recall, which is estimated to have cost the company over $28 billion. SOPs, when combined with a strong quality management system, act as a preventative measure, safeguarding your reputation and preventing the financial fallout of a product recall.

3. Knowledge Transfer and Training: Saving Time and Resources

In today’s dynamic manufacturing landscape, employee turnover is a reality. When experienced workers move on, their expertise can be lost, creating a knowledge gap that can impact productivity and quality. SOPs act as a transferable knowledge base, capturing the collective know-how of your workforce. New hires can be readily trained using SOPs, ensuring a smooth transition and consistent quality from day one. This eliminates the need for extensive, on-the-job training, saving valuable time and resources. Imagine the cost savings if you can onboard new employees quickly and efficiently, minimizing the disruption to your production schedule.

4. Improved Efficiency and Reduced Waste: Optimizing Your Resources

SOPs promote efficient use of materials and equipment. By outlining proper procedures and highlighting areas for potential waste reduction, SOPs can help minimize material usage and equipment wear-and-tear. For instance, an SOP might specify the exact amount of adhesive needed for a specific assembly, preventing over-application and wasted materials. Similarly, SOPs can outline preventative maintenance schedules for equipment, ensuring it runs smoothly and efficiently for longer, reducing downtime and repair costs.

Taking Action: Implementing SOPs for Success

Now that you understand the power of SOPs, how do you get started? Here are some key steps:

- Identify Critical Processes: Start by identifying the most critical processes on your manufacturing floor. Focus on areas where errors are most common, quality is paramount, or efficiency can be significantly improved.

- Develop Clear and Concise Procedures: Write SOPs in a clear, concise, and easy-to-understand format. Use visuals like diagrams and flowcharts to enhance understanding. Don’t be afraid to involve your team members in the development process – their experience can be invaluable in creating practical and effective SOPs.

- Training and Implementation: Once your SOPs are developed, train your team members on the new procedures. Encourage questions and feedback to ensure everyone is comfortable and confident using the SOPs.

- Continuous Improvement: SOPs are not static documents. As your processes evolve and technologies change, your SOPs should adapt as well. Regularly review and update your SOPs to ensure they remain relevant and effective.

Ready to harness the power of SOPs in your manufacturing business? Here are some additional resources to get you started:

- International Society of Automation (ISA): https://www.isa.org/

- The Lean Enterprise Institute: https://www.lean.org/

By implementing clear and well-defined SOPs, manufacturers can achieve significant cost savings through increased productivity, improved quality control, efficient training, and reduced waste.