Reducing Unplanned Downtime with Amazon Monitron: An Industry Insight

Unplanned downtime is a major challenge for companies across various industries. A recent study shows that 82% of companies experience unexpected equipment failures at least once a year, leading to significant financial losses. The need for a proactive maintenance approach has never been more critical.

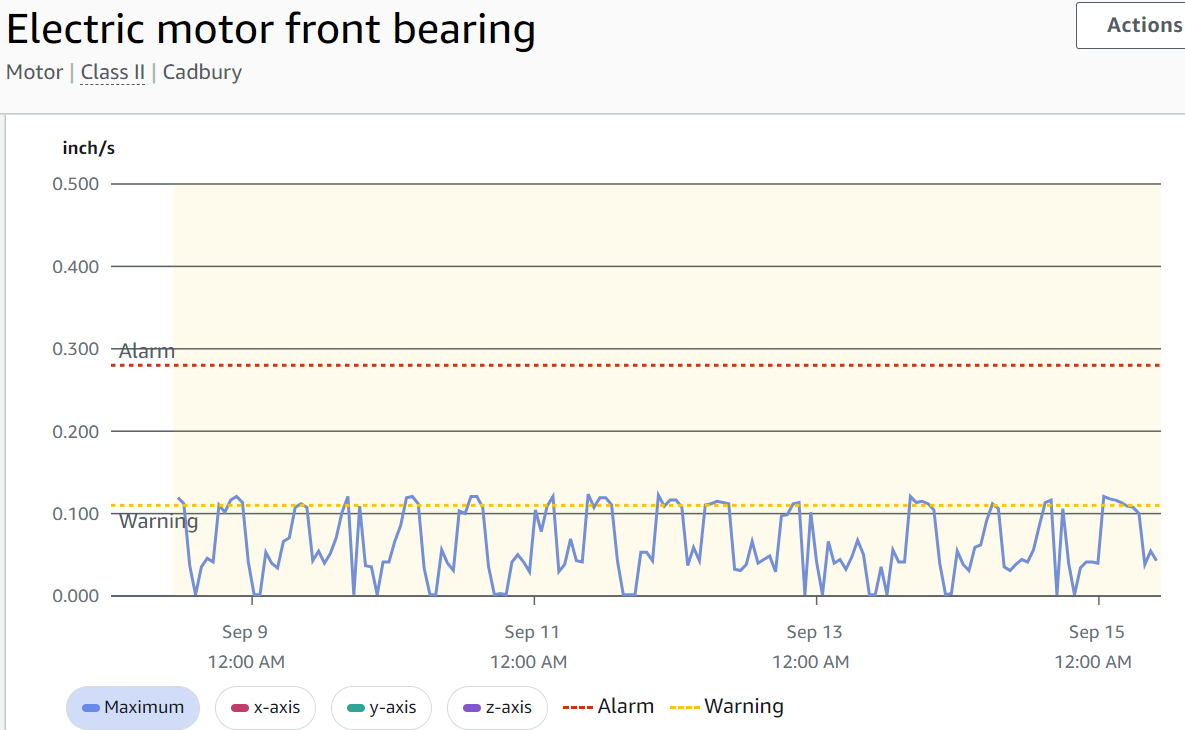

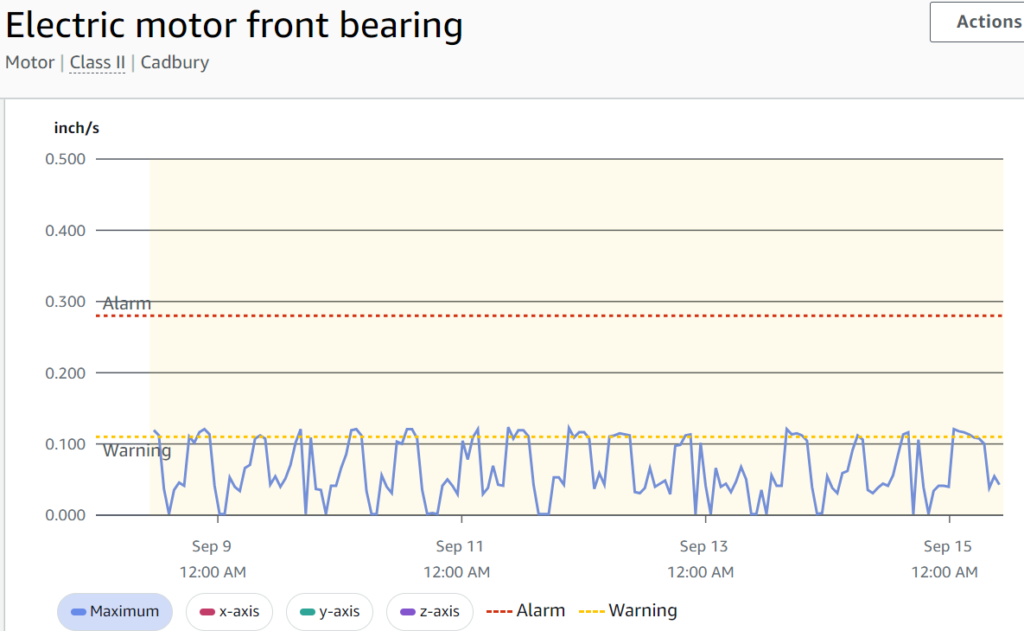

Enter Amazon Monitron, a solution designed to combat this issue. Amazon Monitron uses advanced sensors and machine learning to monitor the health of machinery in real-time. It provides early warnings of potential failures, enabling maintenance teams to address issues before they escalate.

Key Benefits:

- Real-Time Monitoring: Amazon Monitron continuously tracks vibration and temperature data, ensuring that no potential issue goes unnoticed.

Predictive Maintenance: By identifying patterns and anomalies, Monitron helps shift from reactive to predictive maintenance, reducing unplanned downtime.

Cost Savings: Companies can significantly cut costs associated with emergency repairs and lost production with fewer breakdowns and more efficient maintenance practices.

In this blog post, we summarized the challenges of unplanned downtime and how Amazon Monitron is revolutionizing how companies approach maintenance.