Behind-the-Scenes: Implementing Amazon Monitron for Condition Monitoring

Successful condition monitoring requires more than just placing sensors on machinery. It involves meticulous planning, precise execution, and ongoing monitoring. In this blog post, we take you behind the scenes of a recent project where we implemented Amazon Monitron.

Project Overview:

Our client, a leading manufacturer, needed a solution to monitor their critical machinery 24/7. They faced challenges with unexpected failures that led to costly downtime and production delays.

Planning:

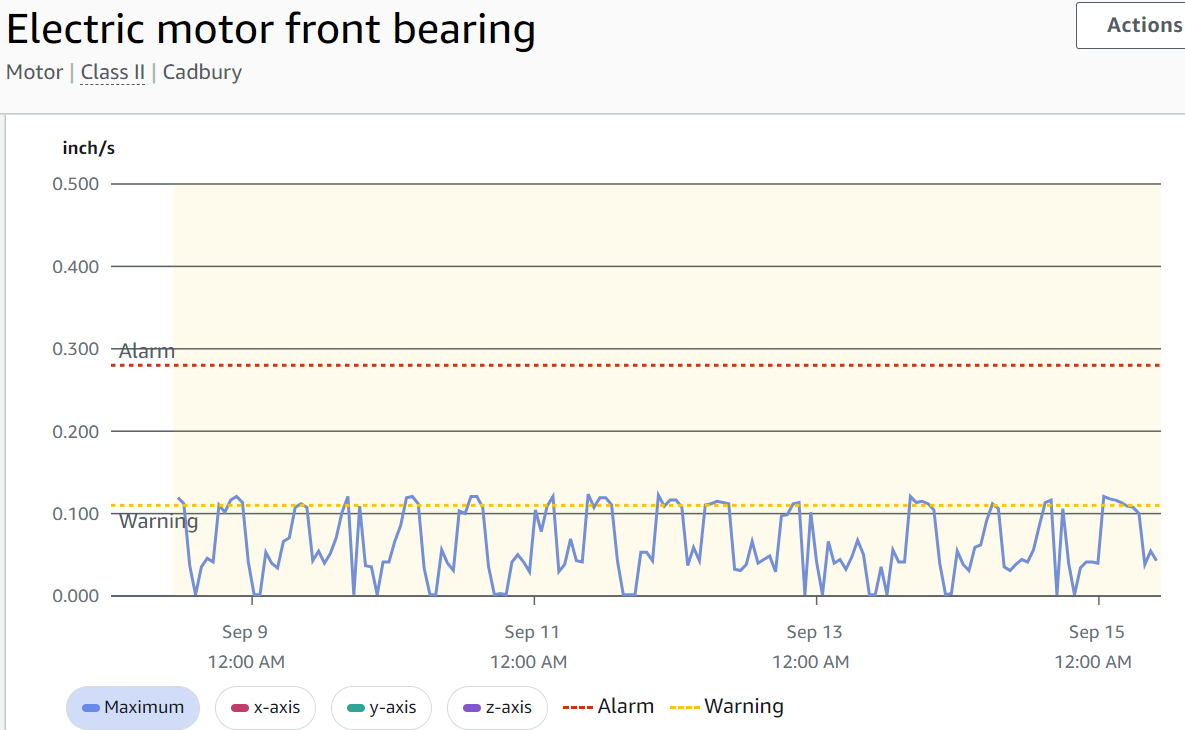

We started with a comprehensive assessment of their equipment and operational needs. We identified key machines where vibration and temperature monitoring would be most beneficial. This phase also included determining the best locations for sensor placement to ensure optimal data collection.

Execution:

The installation of Amazon Monitron sensors was completed over a weekend to minimize disruptions. The wireless nature of Monitron made the process efficient, with no need for extensive cabling or infrastructure changes. We then configured the system to align with the client’s specific operational parameters.

Monitoring and Optimization:

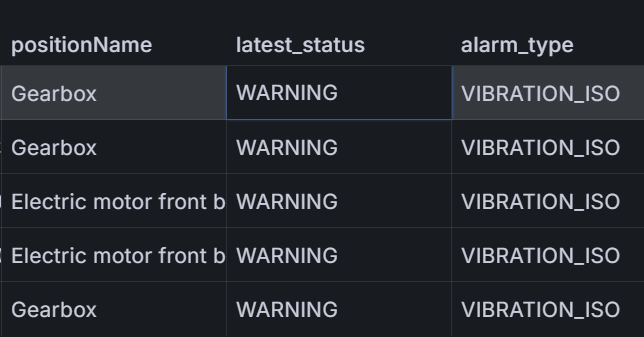

Once the system was live, we worked closely with the client to monitor the data. The first few weeks involved fine-tuning the thresholds and ensuring that alerts were accurate and actionable. Over time, the system proved its value, with early detection of issues that could have led to significant downtime.

This behind-the-scenes look showcases the importance of a strategic approach to condition monitoring. Amazon Monitron is not just a set-and-forget system—it’s a powerful tool that, when implemented correctly, can transform how you manage equipment health.