Harnessing Data Science for Predictive Maintenance

Data science has become integral to various fields, including Industry 4.0, where it plays a crucial role in predictive maintenance—a key component of modern asset management.

In the context of Industry 4.0, massive amounts of data are continuously generated and stored. This data is invaluable for predictive maintenance, which uses data science to anticipate equipment failures and optimize maintenance schedules.

By leveraging advanced mathematical and computational techniques, professionals can identify the root causes of machine failures and quality deviations, minimizing downtime and financial losses.

One of the most significant applications of data science in manufacturing is in predictive and preventive maintenance. This process relies on several key technologies:

1. Sensors

Sensors are fundamental in providing real-time monitoring and measurement of physical conditions. They gather data on various operational parameters, enabling organizations to detect potential issues before they lead to failures.

2. Gateways

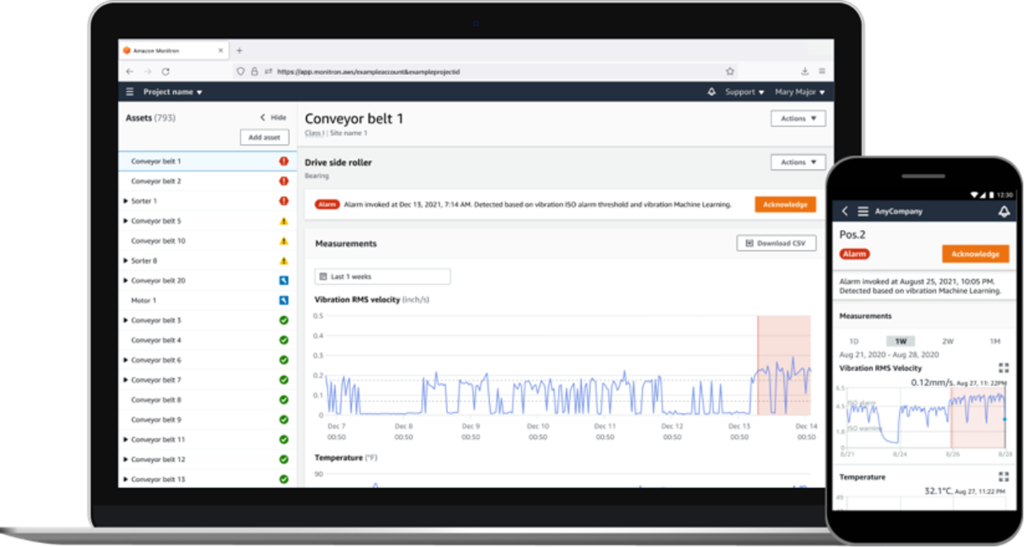

Gateways play a crucial role in securely collecting sensor data and transmitting it to the cloud. This ensures that the data is available for further analysis and decision-making.

3. Condition Monitoring

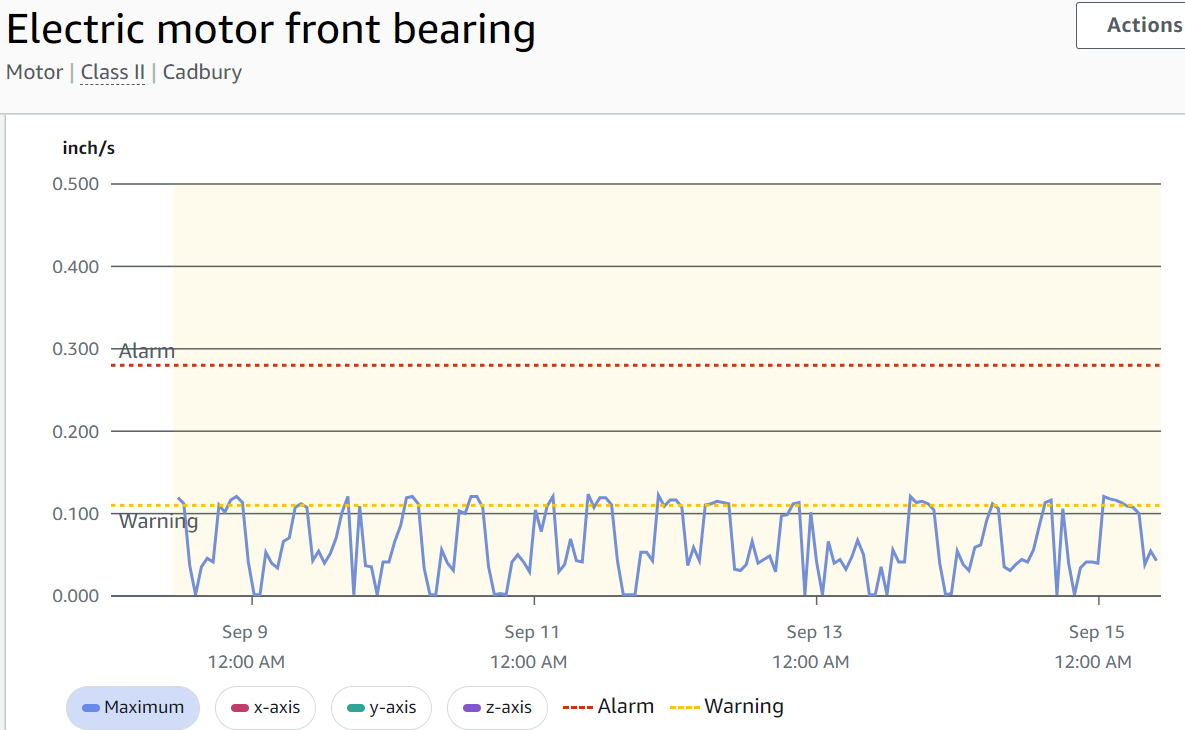

Condition monitoring systems track changes in physical conditions over time. Organizations can quickly detect and address anomalies by comparing real-time sensor data against predefined thresholds.

4. Alerts

Real-time alerts notify stakeholders immediately when potential issues are detected, allowing for prompt intervention to prevent equipment failures or production losses.

5. Advanced Analytics

Advanced analytics are employed to analyze the collected data, extracting actionable insights that help organizations make informed decisions. This capability is essential for predicting when maintenance should be performed to avoid unexpected downtime.

6. Cloud Technology

Cloud technology supports the entire process by providing scalable storage, processing, and analysis capabilities. It allows organizations to access their data and analytics tools from anywhere, ensuring that maintenance decisions are timely and well-informed.