Maintenance metrics

Maintenance metrics, or Key Performance Indicators (KPIs), are crucial for tracking maintenance performance within an organization. These metrics can range from general indicators such as downtime and overtime to specific details like pending work orders.

As a maintenance manager, it is essential to apply due diligence in following up on these metrics as a basis for daily planning and stand-up meetings. This practice ensures that all pending jobs are reviewed and discussed, allowing you to identify and address any issues that might affect the prompt completion of tasks.

A common practice is to review the job status with each technician during planning meetings. This aligns with the principle that “whatever is not measured cannot be monitored, and monitoring breeds commitment.” This approach is not about micromanagement but rather about obtaining daily updates from the team through standardized planning meetings to keep everyone aligned and informed.

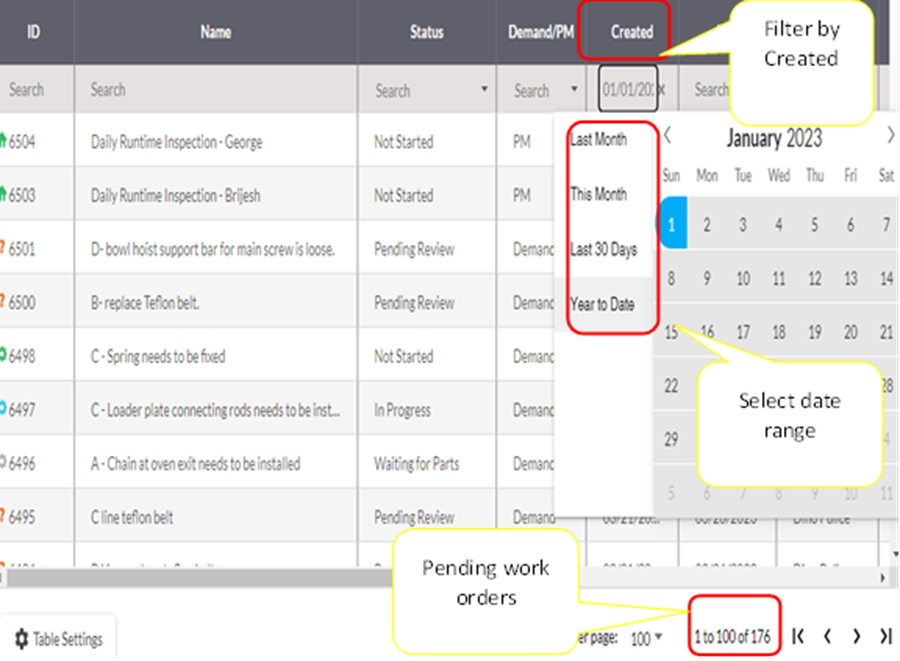

The use of a computerized maintenance management system (CMMS) has streamlined and enhanced the accuracy of this process. A typical example of a CMMS system is HIPPO CMMS. By applying a year-to-date (YTD) filter to the created date column, you can track the most recent data, which is often backdated to the last day of the previous week, depending on the organization’s KPI review schedule.

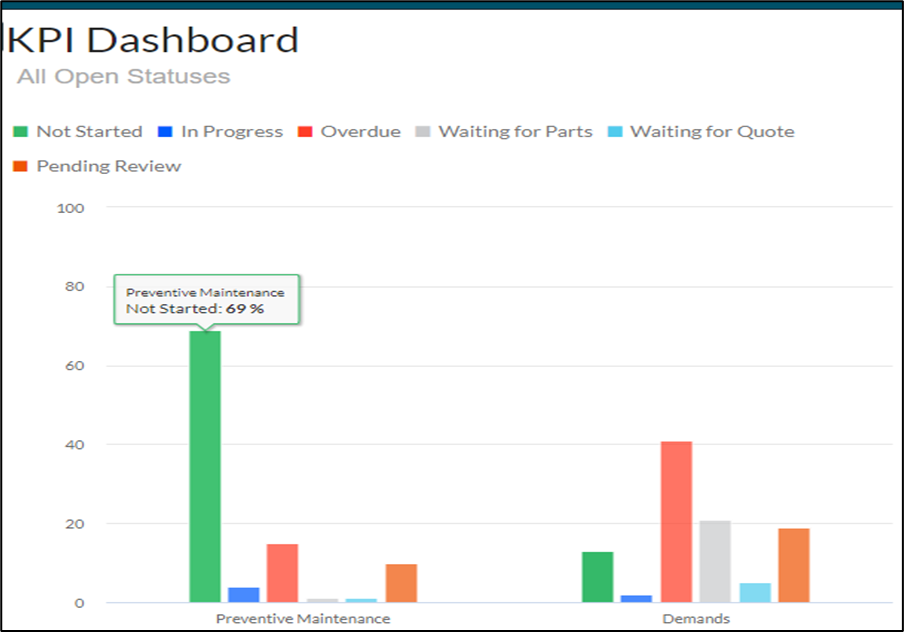

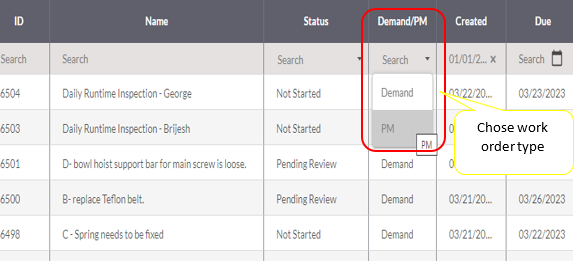

This will give the number of pending work orders that need attention. The focus is to get the job done and not to just close the work order electronically, as has been observed in different scenarios. Next to the filter is the work order type or category. A universal classification is preventive maintenance (PM) and corrective maintenance or demand work order (DM), as shown in the figure below

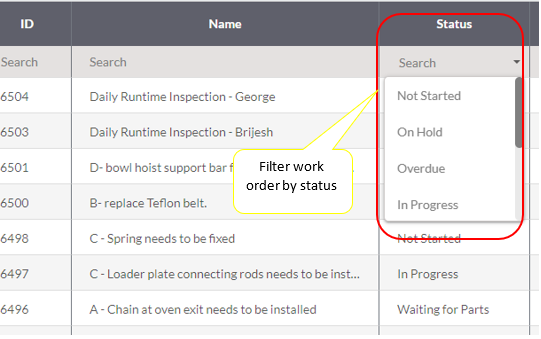

The next part of the metric is to filter the work order status. This will give details of the status of the workers: pending review, not started, in progress, overdue, on hold, etc., as the case may be. This is important to help track all pending work orders and their status. A maintenance manager must see this process as a daily routine.

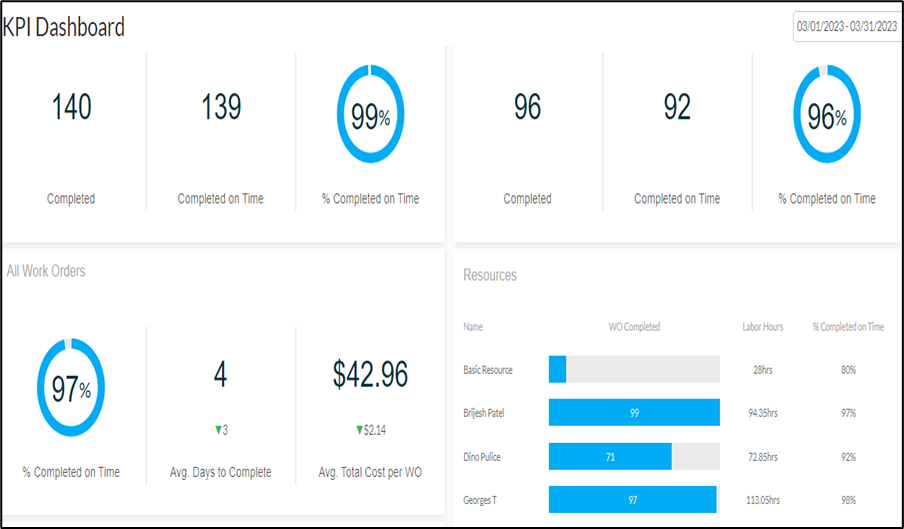

Another important KPI is the number of work orders completed during the week or review. This is particularly important in keeping track of task assignments and execution by the team. With this, the performance of each of the technicians could be monitored, and the functionality of the prevailing preventive maintenance structure could be ascertained. The resulting dashboard is shown below