ABC Classification Matrix

The ABC Classification Matrix is a tool used in inventory management and maintenance to categorize items based on their importance or value. For machines, this matrix helps prioritize maintenance efforts and resource allocation by classifying machines into three categories: A, B, and C.

Category A: High Importance

Machines that are critical to operations and have a significant impact on productivity or revenue. Downtime or failure of these machines can cause major disruptions.

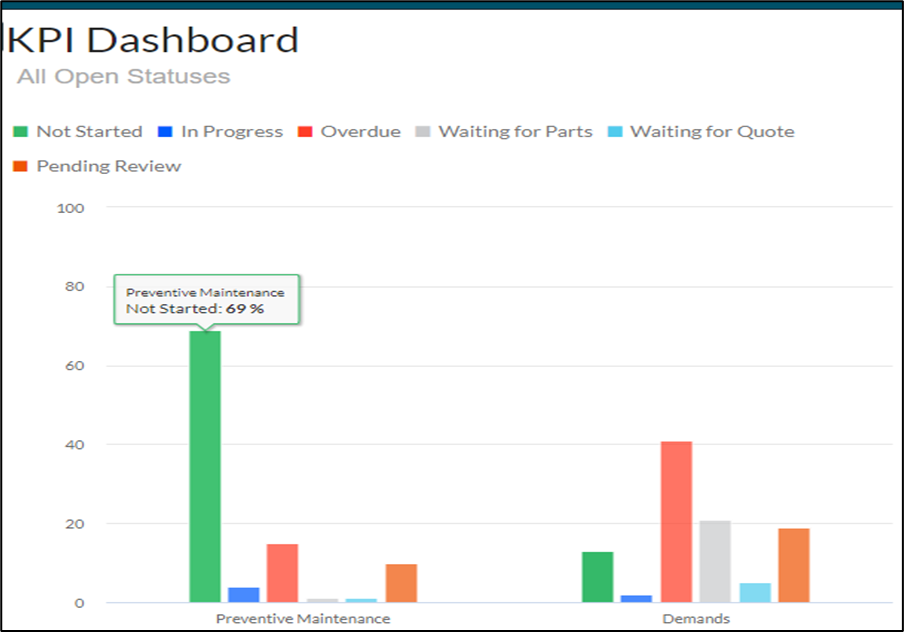

Focus on preventive maintenance, frequent inspections, and quick response to issues. Allocate more resources and prioritize these machines in the maintenance schedule.

Category B: Moderate Importance

Machines that are important but not as critical as Category A machines. They may have a moderate impact on operations.

Schedule regular maintenance and inspections. Monitor performance closely, but allocate fewer resources compared to Category A machines.

Category C: Low Importance

Machines that have the least impact on overall operations. Their failure or downtime has a minimal effect on productivity or revenue.

Perform maintenance less frequently. Allocate minimal resources and address issues as they arise without immediate urgency.

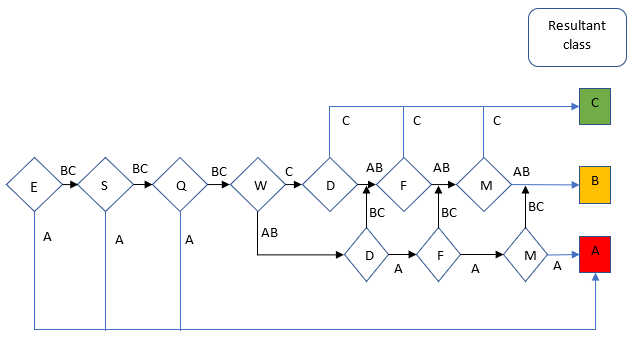

Use the chart below to arrive at the resultant class of your machine.

- E – Environment

- S – Safety

- Q – Quality

- W – Working Time

- D – Delivery

- F – Failure Frequency

- M – Maintainability

#ABCClassification #MaintenanceManagement #MachinePrioritization #OperationalEfficiency #InventoryManagement #PreventiveMaintenance #ResourceAllocation #MaintenanceStrategy #AssetManagement #CriticalMachinery #MachineClassification #DowntimeReduction #MaintenanceOptimization