Preventive Electric Motor Maintenance

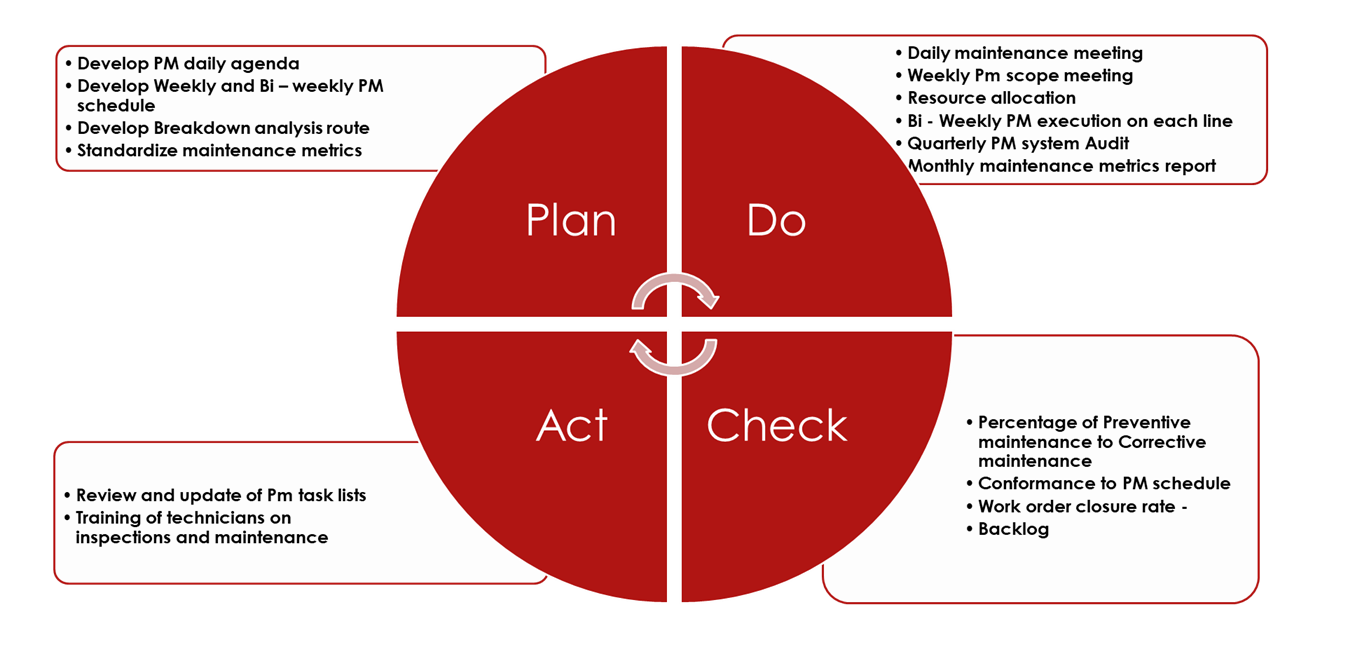

A well-designed preventive maintenance program ensures dependable, long-lasting electric motor operation. Electrical equipment demands regular inspections and maintenance for optimal performance. This is crucial for electric motors. Routine inspections at predetermined intervals throughout a motor’s lifespan are essential. Periodic examinations enable early detection of potential issues, preventing major breakdowns. By conducting thorough inspections, professionals can identify subtle signs of wear, overheating, or misalignment before costly repairs become necessary. Preventive maintenance extends motor lifespan, enhances energy efficiency, reduces costs, and minimizes environmental impact. Embracing this proactive approach maximizes return on investment and demonstrates commitment to operational excellence.

Electric motor maintenance programs aim to prevent critical breakdowns, not just repair them. In plant operations, unscheduled production stoppages or lengthy repair shutdowns are unacceptable. The resulting downtime severely impacts production times. Periodic motor inspections are necessary to ensure optimal operating results.

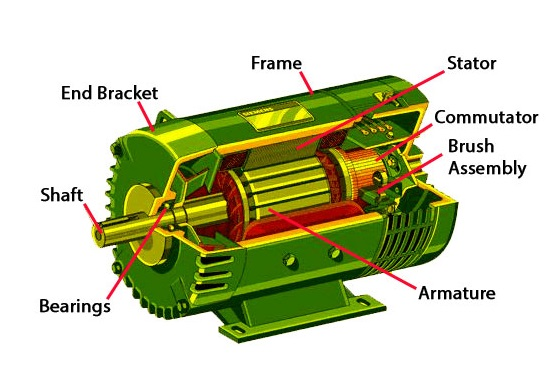

Preventative maintenance programs require detailed checks, and all on-site motors should have an ID number and record log. Motor records should identify the brand, inspection dates, and repair descriptions. Keeping records enables determining the cause of breakdowns, reducing ongoing problems. All maintenance programs should refer to the manufacturer’s technical documentation before performing checks. Simple routine checks for three-phase motors can aid in ensuring a long motor life. These include reviewing service history, noise and vibration inspections, visual inspections, winding tests, brush and commutator maintenance, and bearing and lubrication checks. Inspection and servicing should be systematic.

Inspection frequency and thoroughness may vary depending on factors like the motor’s importance, usage, and environment. An inspection schedule must be flexible and adapted to each plant’s needs. Implementing a well-planned preventive maintenance program is key to dependable, long-life electric motor operation. Regular inspections locate potential problems before serious machinery damage occurs. Detailed record-keeping, following manufacturer guidelines, and conducting appropriate checks maximize motor lifespan and minimize costly breakdowns.

Frequent Checks:

- Remove dust and oil from the motor.

- Ensure oil rings rotate with the shaft.

- Verify oil levels in bearings.

- Visually inspect for oil and grease leaks from bearings.

- Examine the starter switch, fuses, and tighten loose connections.

Every 6 Months:

- Clean the motor, blow out dirt from the windings, and wipe the commutator and brushes.

- Visually inspect the commutator clamping ring.

- Replace brushes if more than half worn.

- Examine and clean brush holders if dirty.

- Check brush pressure and position.

- Remove, clean, and replace oil in sleeve bearings.

- Check grease in ball or roller bearings.

- Verify operating speed(s).

- Examine and tighten loose connections.

- Test current input and compare it with normal values.

- Visually check the drive for smooth running and absence of vibration.

- Inspect motor foot bolts.

Annually:

- Remove and renew grease on the ball or roller bearings.

- Test insulation.

- Clean magnetic dirt attached to poles.

- Check clearance between the shaft and journal boxes of sleeve bearing motors.

- Inspect the commutator for smoothness and slot damage.

- Examine the connections of the commutator and armature coils.

- Inspect the armature bands.